The field of use of ball cranes in the industrial sector includes such a concept as mechanized control of it using one or another method.

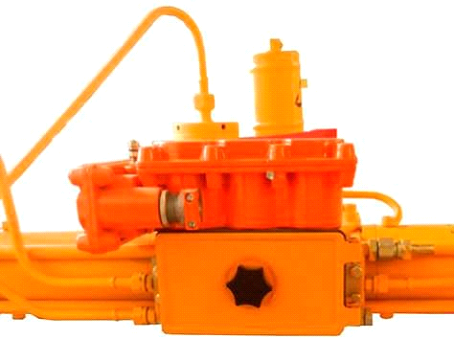

Valve pneumohydraulic actuators

Projects

In places where the use of an electric drive is impossible or for other reasons, pneumohydraulic drives are used. In this case, it is meant to use the pressure of two types of media (air and liquid) in order to set the required position (open / closed) of the closing element of the ball valve.

The ball valve with a pneumatic drive is controlled remotely and does not require the immediate presence of service personnel. At the same time, a force sufficient for the operation of fittings with a large cross-section is created, therefore this type of control is widely used on main pipelines.

Regardless of the design of ball valves with a pneumatic hydraulic drive, gas is supplied under pressure to the pneumatic chamber (one of two), which drives the piston, which, in turn, (directly or through another piston) presses on the fluid of the hydraulic drive. At the same time, the hydraulic force starts the rotary mechanism of the closing element of the crane.

Due to the presence of an interdependent chain (gas-liquid), through which the force is transmitted to the closing element, there is no need to use a bulky hydraulic pump, which is one of the advantages of using a pneumatic hydraulic drive. In addition, the gas creates a uniform pressure immediately throughout the system, and its pulsation, which occurs when the pressure changes, is smoothed out by the hydraulic drive and does not have a direct effect on the working element.

There are different pneumohydraulic drives according to their technical characteristics, climatic performance and supply voltage. In the absence of power, the system can work as a conventional hydraulic drive from a manual hydraulic pump.